A frequent question that we get on 100G QSFP modules is cost: How much is it? How much does it cost?

Well, the short answer is – it depends. It’s impossible to give one same price as it is based on many different factors. But we will try to answer this important question with enough details and actual price ranges that you can use as a reference as you consider your next 100G QSFP28 purchase.

Let’s take a look at different factors that could affect 100G QSFP28 optical module cost.

Engineering Development Considerations

While optical transceiver development has gotten simpler over the years, it does involve full engineering development to design, validate, and qualify. Generally, the two main milestones in this phase are Design Verification Test (DVT) and Qualifications Test.

DVT confirms that the finished product meets technical performance objectives as set out in the original engineering design. Key design paraments such as output power, receiver sensitivity, bit error rate are verified in this testing and documented.

Qualifications Test primarily deal with reliability. Several well-defined reliability tests based on common industry standards GR-468-CORE and MIL-STD-883/202 are conducted. These tests include temperature cycling, moisture resistance, damp heat, shock and package drop test, among others.

Engineering development and test expenses will be reflected in the final 100G QSFP28 optical module cost.

Product Cost

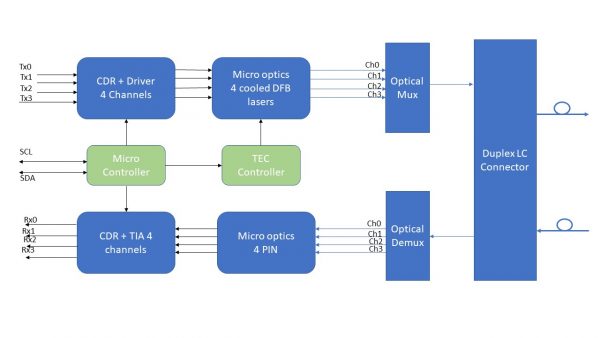

Bill of Materials Cost, or BOM cost, includes the costs of all building materials necessary to make 100G optical transceivers. Key materials include:

- Lasers/transmitter sub-assembly (TOSA)

- Photodetectors/receiver sub-assembly (ROSA)

- Chipsets: these are IC’s are used for controlling optical components and conditioning electrical signals. These include clock and data recovery, amplifiers, and laser drivers.

- Remaining materials include optical mux/demux, mechanical case, and other minor components.

Production: This involves labor, equipment, and other direct resources necessary for product assembly, manufacturing, and testing. As with all electronic manufacturing, high yield rate is an important factor in production to keep production costs in control.

Internal Business Considerations

Overhead and fixed costs are not directly attributable to actual optical module production but overall necessary expenses for any business to operate. In addition to engineering development cost discussed before, other overhead expenses include rent, utilities, sales, marketing, administration, and technical support.

Profit margin is an important contributor.

Some companies may have specific financial target they need to meet at some point. A good example would be a public company who decides to offer significant price discount at the quarter end to meet their quarterly shipment goal.

Business strategy and priorities can affect product pricing significantly. A company may decide to offer a new product at lower than normal prices in hopes of expanding the customer base quickly and thus gaining market share.

Customer Considerations

Especially in a B2B business like optical transceivers, purchase volume and customer relationship play an important role in product costing. It’s almost a given that a repeat customer who buys 500 units of 100G QSFP28 modules every quarter receives much better pricing than another customer who makes a one-time purchase of 100 units.

Some customers may request customization of optical modules in their own labels, packaging, or programming. This will increase final cost as additional process and testing need to be set up separately from the standard process. Here are actual examples of custom labeling and packaging:

External considerations

Component Supply

Key components such as lasers and high-speed ICs are dominated by a few manufacturers in Asia and the US. While the supply chain and thus pricing is normally stable, unexpected natural disasters like the severe 2011 earthquake and tsunami in Japan and the current worldwide COVID-19 pandemic have severe impact on key component supply and pricing.

Recent trade disputes between the US and China created uncertainty and a higher tariff on optical modules coming from China into the US.

Actual Cost Examples

So you ask, after all factors and considerations, how much do 100G QSFP28 modules really cost?

The following is an example of the module cost based on our company’s records from January through September 2020. While this is not absolute information, it should serve as a good reference point for the price of a well-designed and fully qualified 100G QSFP28 optical transceiver.

- 100G QSFP28 SR4 (100m) cost ranged from $220 to $295 depending on purchase volume and customization requirements

- 100G QSFP28 CWDM4 (2km) cost ranged from $380 to $420

- 100G QSFP28 LR4 (10km) cost ranged from $700 to $850

- 100G ER4 Lite (40km) cost ranged from $3000-$3500

Final takeaways

Cost is one of the most important attributes in your purchase decision making. We explained how cost is calculated for 100G QSFP28 optical modules based on a wide range of engineering, production, business, and external considerations. It’s best if you have a clearly thought-out list of the most important factors for your decision-making. We also recommend that you educate yourself on prospective supply partners with a list of questions like the following.

- How do you approach engineering development?

- What kind of product design verification is performed?

- Can you share your qualifications test report?

- How is your manufacturing process set up?

- What steps are in place to ensure proper quality control?

- Do you offer local technical and customer support?

- How will my cost improve as my purchase volume and business relationship get established?

- Who do I contact and how will you help if I run into problems?

Our team is also here to help you. A well-informed customer is a happy customer.

If you have any technical or business questions on 100G QSFP28 optical modules, feel free to contact us at info@vitextech.com.

Related Products