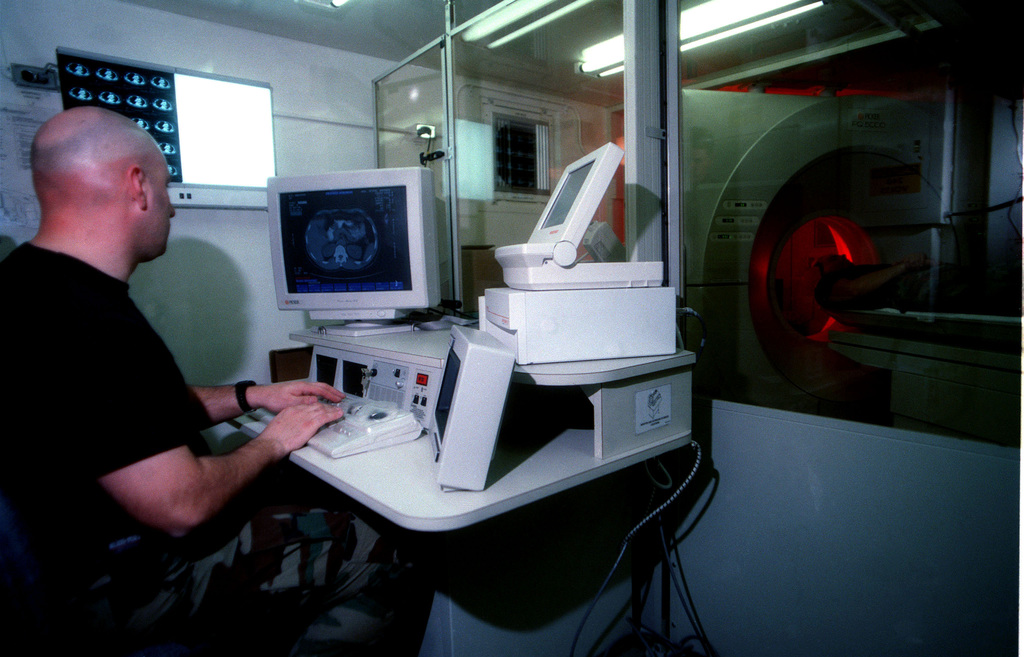

Medical procedural and diagnostic equipment depend on crystal clear visualization from rapid, continuous video data feeds

Medically-certified video extenders transfer data from specialized equipment to high resolution monitors with high bandwidth, pinpoint accuracy and near-zero latency. Whether the visualization screens are nearby or at a distance, Vitex video extenders offer the highest quality to ensure reliability and throughput.

High res, crisp pictures help medical practitioners make the right decisions

Robotic surgical systems and diagnostic cardiology and neurology imaging equipment depend on the rapid transmission and processing of enormous amounts of critical data to create detailed imaging for surgeons and diagnosticians. Continuously transmitted, the data must be immediately and clearly displayed on a complex arrangement of screens and monitors.

Vitex video extenders deliver rapid transmission of high bandwidth data to create accurate, uncompressed, laser-sharp images with 4K/8K resolutions. Performance for critical, invasive procedures is seamless and uninterrupted.

Two common solutions for medical imaging

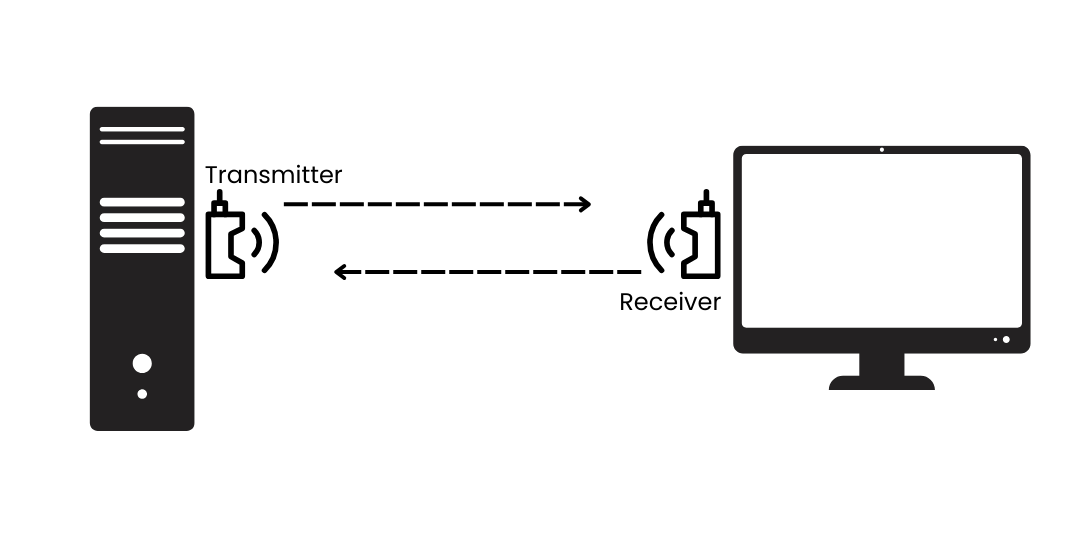

Straight fiber video extenders

Each fiber cable (available in multiple lengths) has a dongle at either end that plugs a source and a display side in the protocol that you need (VGA, DVI, KVM, HDMI, DisplayPort and USB). This simple, plug-and-play solution offers EMI shielding (or immunity) and data security with minimal connections.

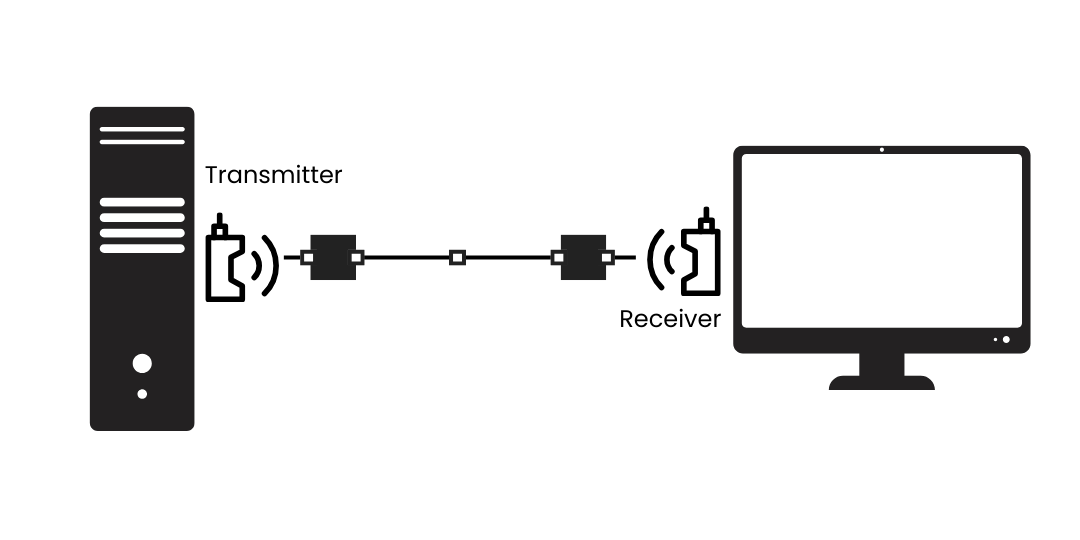

Detachable fiber video extenders

Designed for complex connections, this is an assembly that offers more flexibility If your source and monitor have different connections, say DVI at one end and connecting to DisplayPort or HDMI, the assembly would have modules that plug directly into the ports and the cables plug into the dongles. For settings with small wireways, the detachable cables are much easier to feed through walls without the dongle ends attached. And, if you need to move the equipment or perform servicing, it’s easy to disconnect and reattach the cables as needed quickly.

Both options offer complete input/output electrical isolation, immunity to electromagnetic isolation (EMI), superior data security (over copper) and incredibly easy installation, troubleshooting and maintenance.

Success Story

Pure fiber DisplayPort™ video extenders make pioneering 3D medical imaging crystal clear

How a video-over-fiber solution with US-based support solved a data bandwidth problem

IEC certified for all medical electrical equipment

Vitex develops and supplies optical products that offer safety and reliability with high performance. This includes products for the medical device OEM market that must be compliant with IEC/EN 60601-1 and IEC/EN 60601-1-2 for medical electrical equipment.

Data transmission-based healthcare equipment depends on a robust facility network

It’s not just medical visualization systems that are more demanding of quality data transmission. Hospital infrastructures are expanding and with it are the capabilities and reliance on high capacity, shielded, secure networks. Whether it’s new construction or facility upgrades, bandwidth, cabling, clarity, flexibility and security are critical for operational and connectivity and patient care.

Fiber optic transceivers, cables and components power medical center networks and medical devices to solve the limitations of copper wire cabling:

- No electromagnetic interference with other electrical devices

- Robust – resistant to high temperatures, water and radiation

- Fast and reliable transmission for continuous, high volume data and longer distances

- Galvanic isolation

- Secure – very difficult to split

- Non-toxic

- Flexible, strong, slim form factor and lightweight – perfect for tight bends and tight spaces

- Low maintenance

Do you have a fiber optic challenge that needs an expert?

Fiber optic technology is tranforming healthcare. How?

Learn why the advantages of fiber optics are powering the development of medical diagnostics and procedures. Even operating rooms are upgrading to fiber optics to continuously feed video from devices to multiple destinations and multiple displays.

Vitex’s in-house testing lab

The added value our testing lab offers for healthcare OEM product validation

What our medical equipment OEM customers say

“As a developer of medical systems, we are required to comply with EMC standards for medical devices. Vitex devices met this requirement every time we tested them. The other devices we tested did not even come close.”

– Jon

Engineering Manager, Leading Medical Manfacturer

“We did test 3 different DVI converter sets & the M1-201CA-TR did perform the best of all of them repeatedly.”

– Tom A.

Director, PLM, Tier 1 Communication Network Co.

Straight talk from New Jersey

Vitex is based in New Jersey where you’ll find our lab, warehouse, sales and support team just a phone call or email away.

The perfect fiber optic solution is here

Developers and engineers often require a unique set of specifications for new equipment prototypes and designs. Fiber optic cables and connectors can solve problems caused by the environment (temperature, humidity), the application (combination functions, power) or the network (connectors, distance).

Talk to Vitex about specialty hybrid and custom fiber products for your network, prototype or production equipment. We’ll work with you to find the perfect solution.

Do you have a medical facility or equipment challenge that needs an expert?

Learn more

By Michael Ko We started 2024 with a new company tagline, “Here to listen. Driven…

By Jose Suarez In today’s high-performance environments, reliable video transmission is mission critical, whether it’s

How Vitex Pure Fiber Detachable Video Extenders Solve EMI ChallengesContinue reading >

December 9, 2024 – Hackensack, NJ – Vitex, a leading provider of advanced fiber optic

Vitex Recognized with 2024 EXFO World Class Supplier AwardContinue reading >