Table of Contents

Comparing glass and plastic optical fiber is simple. Your first associations are not entirely wrong. But your purpose and fiber optic application will dictate what you need.

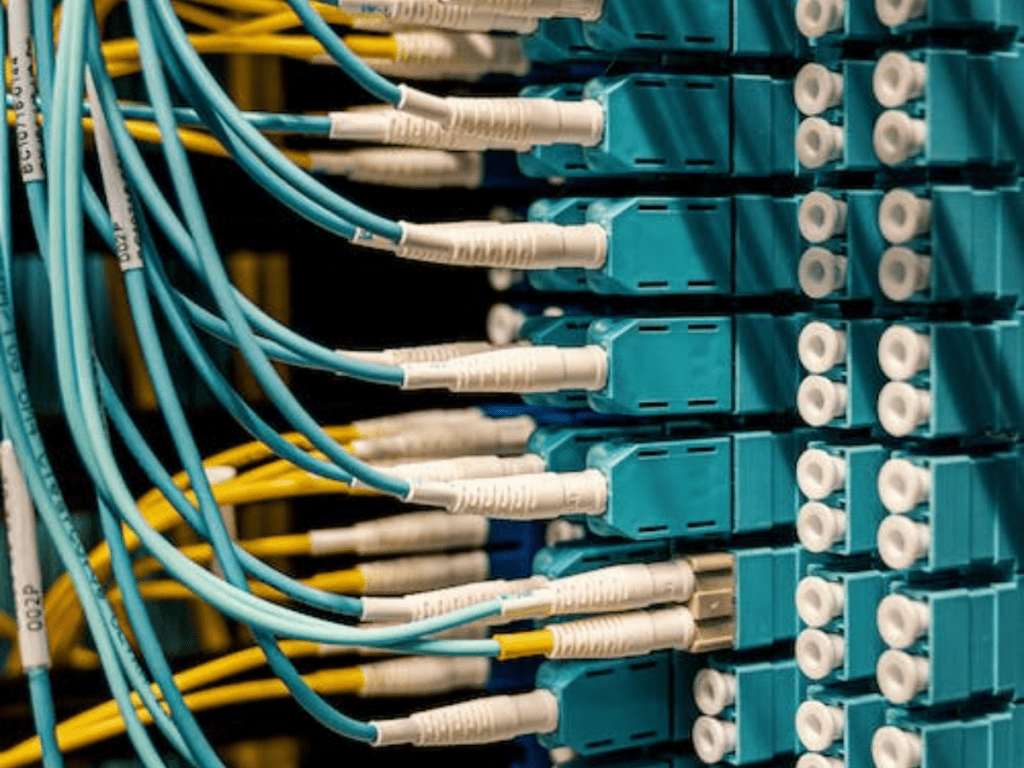

Glass vs. Plastic Optical Fiber

Glass optical fibers are tiny strands of glass bundled together encased inside sheathing typically constructed of stainless steel or PVC. An average assembly consists of several hundred glass fibers bundled together. The sheath protects the glass, making the construction sturdy.

Plastic optical fiber (POF) is constructed from plastic or polymeric materials. The core’s large diameter consists of PMMA (acrylic). Plastic cables have an unterminated end which makes it easy to cut.

Since optical fibers transmit light, often long distances, the material construction makes the difference.

Glass optical fiber can transmit large amounts of data over long distances without loss. It can also withstand extreme temperatures. These capabilities have made glass an industry choice for many commercial and industrial applications.*

Glass Optical Fiber

Advantages

- Versatile and robust, rugged

- Have an impressive temperature range: from -40°F to 900°F

- Optimized for small spaces

- Have high data transmission capacity with lower loss

- Can handle wet and corrosive environments without degrading

- Able to transmit a much wider spectrum ranging from UV, visible, and infrared light

- Exhibit less loss through the system

- Can be custom-built to fit a specific space or environment

Disadvantages

- More expensive to install

- Product cost is higher but has come down in recent years

- Breakage of individual strands, often caused by sharp bending or continued flexing, can be a problem

Uses and Applications of Glass Optical Fiber

- Commercial and industrial applications requiring transmission long distances

- Hot temperature environments including furnaces, ovens, condensers in large engines

- Extremely low temperatures like cold storage warehouses

- Compatible with visible red and infrared light and many types of fiber heads

- Some configurations can operate within vacuum environments

Vitex products including video extenders, active optical cables (AOCs), and fiber cables are constructed of premium glass optical fiber unless specified otherwise.

Plastic Optical Fiber

POF is cheaper, easier to install, and practical. It’s malleable in tight spaces.

Advantages

- Very flexible in tight spaces

- Durable and strong

- Lightweight

- Can withstand vibration and unstable environments

- Lower cost compared to glass

- Easy to install

- Less signal attenuation than glass fibers

- Can be cut to length in the field

Disadvantages

- Cannot sustain extreme temperatures

- Cannot transmit long distances

Uses and Applications of Plastic Optical Fiber

- Short-range network transmission, broadband access networks

- Data communications

- Decoration, illumination

- Cave or automobile lighting and intelligence systems

Conclusion

Choosing between glass and plastic fiber optic cables is not difficult when you understand what each is suited for. But as in any business and/or engineering decision, these useful tips can spare you difficulties and unnecessary expenses down the road.

Tips

- The quality of glass in cables makes a huge difference. Select manufacturers have a reputation for quality materials and construction. Vet your vendor carefully to ensure you are getting high quality materials at reasonable costs. Consider these factors when purchasing fiber cables.

- For most commercial uses, glass is a better choice, particularly when ruggedness, ability to withstand temperature extremes, high information transmission over long distances with low signal loss are required.

- The cost of glass optical fiber has come down making it more appealing.

- If cost is a major priority, you need to install cables in tight spaces or require short-range transmissions, or if you want to be able to cut cables easily, POF is more suitable.

- Choose a vendor who has considerable experience with these products.

Vitex, based in northern NJ, has been providing fiber optic products and solutions to clients in multiples industries since 2003. We offer a variety of glass optical fiber cables and POF upon request, sourcing our materials from high quality industry-leading manufacturers. Our team of experienced engineers offer US-based technical support and customized solutions. Contact us to discuss your next project.

Related Products