Optical transceivers are the end components of any optical communication link to facilitate data transfer. These transceivers are connected to each other using optical fibers. They use “light” signals to carry data at a blazing fast speed. These transceivers comprise of various optical, electrical, and mechanical components such as transmitter, receiver, ASIC, outer chassis etc.

During its lifecycle, a transceiver is subjected to tough environmental and physical conditions. Typically, once a transceiver is plugged into a switch, it stays connected for a few years unless the equipment becomes faulty or there is a major upgrade to the network. During this time, it goes through different temperature cycles and corresponding mechanical stresses This is especially important if the transceivers are used in extreme weather locations. For this reason, transceivers are classified under three operating temperature ranges:

- Commercial (0 to 70°C)

- Extended (-20 to 70°C)

- Industrial (-40 to 85°C)

Typical datacenter applications can use Commercial temperature marked transceivers. For outdoor applications, Extended or Industrial temperature marked transceivers should be used. Extended and industrial grade transceivers go through extreme temperature cycle testing and hence require special components to withstand these conditions. For this reason, extended/industrial grade transceivers are very expensive and could be difficult to source. The following tests are performed under extreme temperatures to ascertain a transceiver’s quality:

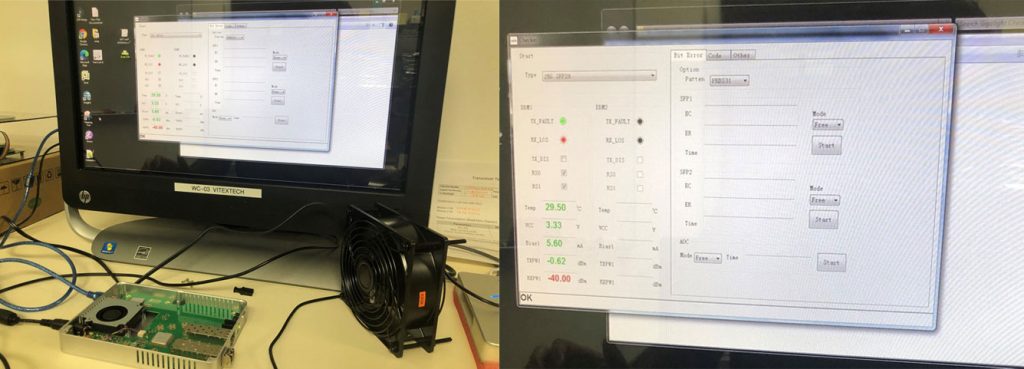

- BER testing

- Calibration – Eye-diagram analysis & voltage/current measurements

- Optical spectrum analysis

- Aging & reliability testing

- Switch testing

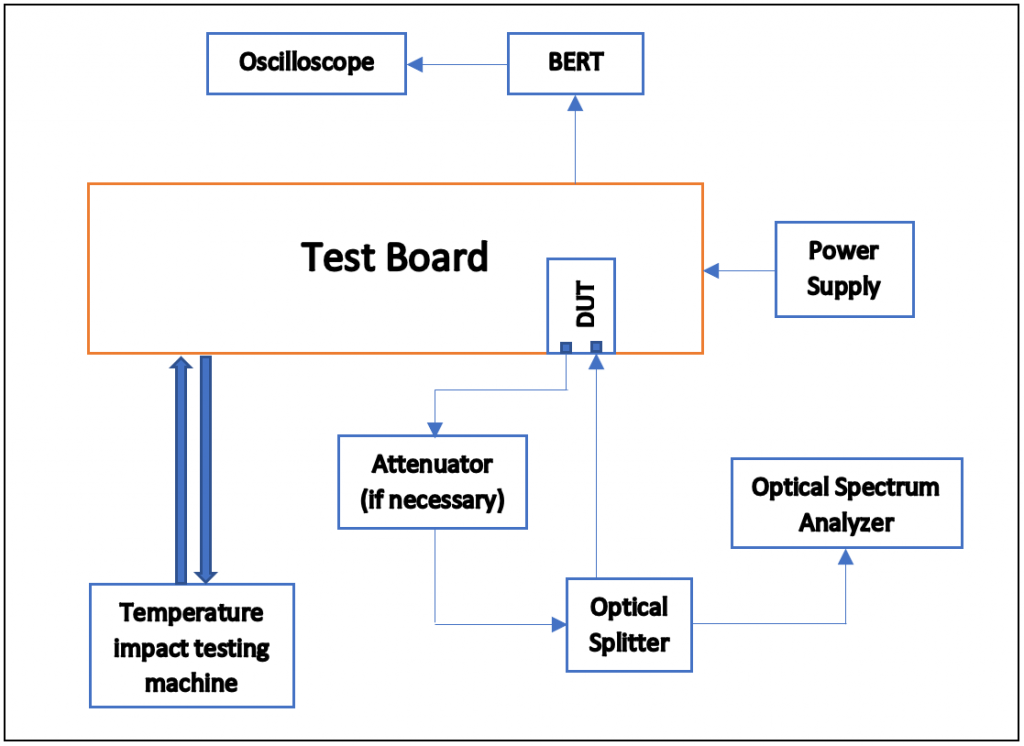

Here, the DUT (device under test) can be any SFP/SFP+/XFP/QSFP/OSFP transceiver.

The “Temperature Impact testing machine” is used to perform temperature testing. It changes the temperature of the DUT and allows for BER, calibration and spectrum analysis measurements to be taken simultaneously.

Conclusion – Transceivers are classified as Commercial, Extended, and Industrial grade based on their operating temperature ranges. They all undergo rigorous testing before going into production stage. One should select the right temperature grade transceiver depending on the type of application they intend to use the transceiver in.

For questions on industrial temp. optical modules or transceiver testing, feel free to contact us at info@vitextech.com.

Related Products