Optical multiplexers (muxes) and demultiplexers (demuxes) form the foundation of DWDM networks deployed by the telecommunications industry. In addition to their use at terminal points, mux/demux components are also used as building blocks of advanced network elements such as optical add/drop multiplexers (OADMs) and optical-crossconnect switches.

This post talks about different mux technologies currently used in the industry.

Thin-film filters (TFFs) were first used in low-count WDM systems. TFFs function by filtering wavelengths serially. The thin-film filter is designed to transmit a specific wavelength channel and reflect all other wavelengths. TFFs use concatenated interference filters, each of which is fabricated with a different set of dielectric coatings designed to pass a single wavelength. They work well for low channel counts but have limitations at higher channel counts due to size and accumulated insertion losses.

As DWDM systems expand beyond 40 channels, channel spacing becomes less than 50 GHz. A 50-GHz filter typically requires several hundred layers of coating to create narrow-band filters that can separate and isolate individual wavelengths. With so many layers being deposited, errors due to local film thickness variation and density alternation increase, reducing the yield of useful filters.

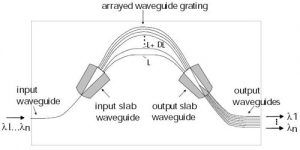

Enter AWGs. In contrast to TFFs, AWG devices use a parallel multiplexing approach that is more conducive to high-channel-count applications. AWGs are compact, single-stage filters that deploy planar waveguide technology. They consist of Free Propagation Regions (FPRs) and waveguides interconnecting the FPRs. The waveguides have different path lengths leading to constructive or destructive interferences in the output FPR, and therefore multiplexing/demultiplexing.

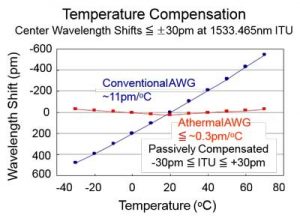

However, if the temperature of an AWG fluctuates, the channel wavelength will change according to the thermal coefficient of the material used.

Vitex offers athermal AWGs completely immune to extreme temperature variations making them ideal for outside plant applications.

The major advantages of an athermal AWG are that there is no need for power supply or temperature monitoring of the AWG device. In Vitex athermal AWGs, athermalization is achieved by mechanical compensation.

AWG Advantages & Applications

The key advantage of AWGs over TFFs is that their cost is not dependent on wavelength count making them extremely cost-effective for high channel count applications. The other advantage of the AWG is the flexibility in selecting channel numbers and spacing. As a result, various kinds of AWGs can be fabricated in a similar manner. Integration is another key benefit of AWG. Vitex offers integrated Mux/Demux modules and AWG based Optical Channel Monitors.

AWGs especially athermal AWGs are a great choice for cost-effective future proof communication networks. Our latest product, ultra-wideband AAWGs feature “super flat tops” to target 400-Gbps network applications.

If you have any questions, please contact Vitex at info@vitextech.com